EDM Wires : Standard Brass EDM wire vs Coated Brass EDM wires.

Standard Brass EDM Wires

All standard Brass EDM wires are composed of a homogeneous binary-copper zinc alloy with zinc contents ranging from 35 – 40 weight percent.

It is known that alpha phase brass is easier to deform than beta phase brass so the most common binary Cu/Zn alloys have 35% (Asian) and 37% (European) zinc contents.

These Brass EDM Wires contain the maximum zinc content available in alpha phase brass which has a balance between optimum vaporization and electrical conductivity.

Coated Brass EDM Wires

Zinc Plated EDM Wire was the first attempt to attain higher cutting speed than standard or plain brass EDM wire by electroplating a thin pure zinc coating onto the surface of a single phase alpha brass alloy core. The thin coating thickness limited the height of the workpiece to 3 – 4 inches.

Diffusion Annealed Coated Wire increases height limitations. The workpiece height limitation faced by “A-Type” wires was overcome by diffusion annealing which is a well-known metallurgical phenomenon where two elements intermix, driven by a concentration gradient, when heated to an elevated temperature.

Gamma Phase Coated Wire is a brittle inter-metallic alloy (Cu5Zn8) with a high zinc content (approximately 65% Zn) which can also be synthesized by a diffusion anneal. However, when such coatings are wire drawn subsequent to the diffusion anneal, the coating will fracture due to its brittleness and redistribute around the wire circumference creating a discontinuous layer sometimes described as a “porous layer” which promotes turbulent flow enhancing the flushing of debris.

Multi-Phase Layered Coated Wire In addition to the three previously brass phases (Alpha, Beta, and Gamma Phase), there is one more brass phase that has unique properties that can be utilized in EDM applications – Epsilon Phase Brass (approximately 85% zinc content). All of these phases can be arranged in various combinations to take advantage of their individual physical and chemical properties. Examples of these combinations are Gamma X, Gamma D, and Epsilon.

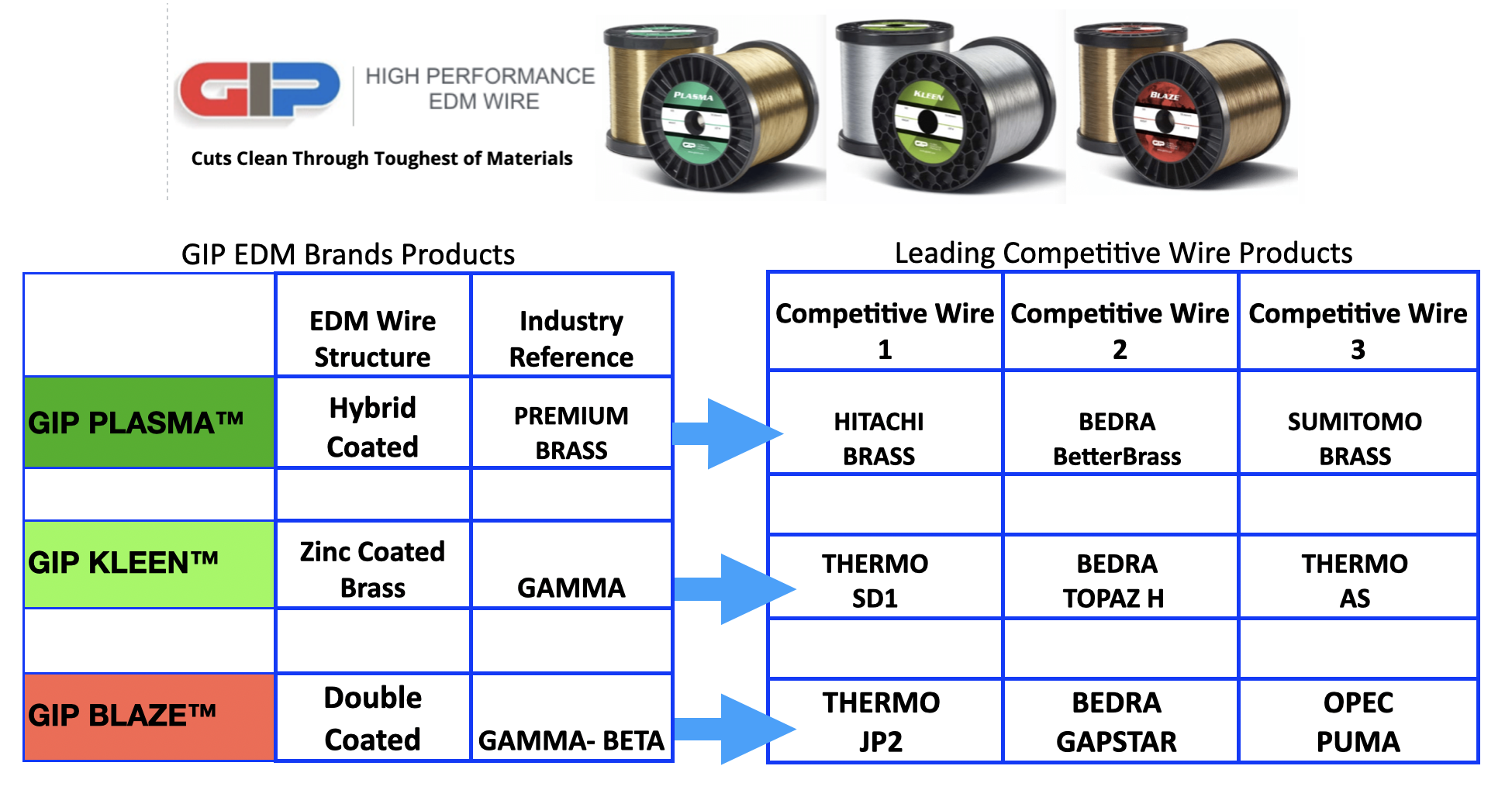

Global innovative Products (GIP) High Performance EDM Wires

GIP PLASMA™ High Performance Hybrid-Coated EDM Wire is competitively priced against Premium Brass wire products from OKI, Hitachi, Sumitomo. Shop PLASMA™ EDM wire for an economical solution for improving cycle times and reducing operating costs.

• Exceptional cleanliness

• 20% faster vs brass wire

GIP KLEEN™ is a unique US Patented EDM wire comprised of a layer of Gamma-Brass (Cu5Zn8) which includes proprietary additive elements creating a unique gamma phase inter-metallic zinc compound which works in concert with a thin oxide surface layer to reduce flaking.

Bedra® Intelligent EDM Wires

Bedra® Boline Brass EDM wire is the first collaboration between Powerway and Berkenhoff Gmbh after their acquisition in 2015. Combining high quality German production standards with the scale and efficiency of Asian manufacturing, Boline Brass delivers solid performance at a competitive price. Outstanding auto-threading capability. Excellent straightness. Extremely clean and smooth wire surface.

Bedra® Boline H Coated EDM Wire. Possesses stable cutting performance. Cutting speed is improved by more than 15% when compared with ordinary copper wires. Widely applied in machining of high precision tools and components.